summary

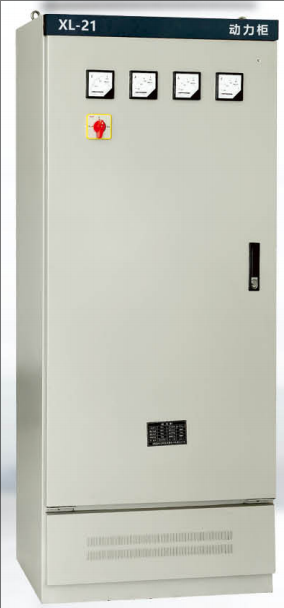

XL-21 type low-voltage power distribution cabinet is suitable for power distribution in power plants and industrial and mining enterprises in three-phase four-wire or three-phase five-wire systems with AC voltage of 500 volts and below. XL-21 type low-voltage power distribution box is an indoor device installed against the wall and maintained in front of the screen.

design feature

The XL-21 type low-voltage power distribution cabinet is a closed system, with its casing made from bent steel plates. The knife switch handle is mounted on the upper part of the right column at the front of the cabinet, facilitating power switching. A voltmeter is installed in front of the cabinet to display the bus voltage. The cabinet has a door at the front, which, when opened, exposes all internal components for easy maintenance and inspection. This type of distribution cabinet uses domestically designed components, featuring a compact structure, easy maintenance, and flexible circuit configurations. In addition to air circuit breakers and fuses for short-circuit protection, the cabinet also includes contactors and thermal relays. The front door can be fitted with operation buttons and indicator lights.

Use environmental conditions

◆ Ambient temperature: -50℃~+40℃, and the average temperature within 24h does not exceed +36℃;

◆ Altitude: not more than 2000m;

◆ Relative humidity: not more than 50% when the surrounding air humidity is +40℃;

Higher relative humidity can be achieved at lower humidity levels (e.g. 90% at +20℃) allowing for moderate frosting given the variation in temperature:

◆ The inclination of the equipment to the vertical plane should not exceed 5° during installation, and the equipment should be installed in a place without violent vibration, impact and corrosion.

Use, maintenance and overhaul

The power distribution box shall undergo the following inspections and tests before being put into operation after installation or maintenance (the inspection and test after maintenance shall be determined according to the quality of maintenance).

◆ Check whether the electrical equipment and secondary wiring installed in the power distribution cabinet meet the drawing requirements.

◆ Check whether the knife switch and air switch used for operation are flexible, and there should be no jamming.

◆ Check whether the contact of the installed electrical equipment is good and whether it meets the requirements of the electrical equipment itself.

◆ Check whether there are other foreign objects inside the power distribution cabinet and whether the fastening screws of each part are loose.

Technical parameters of main equipment

Knife fuse combination switch

model | rated current (A) | Rated current of melt (A) | remarks |

HR3-400/34 | 400 | 150,200,250,300,350,000 | No melt is present when isolating the blade |

Rent transformer

model | rated current (A) | secondary current (A) | remarks |

LM-0.5 | 75、100、150、200、300、600 | 5 |

model | fuse | Rated current of fuse (A) | remarks |

RL1-15 | 15 | 2、4、5、6、10、15 | |

RL1-60 | 60 | 20、25、30、35、40、50、60 | |

RL1-100 | 100 | 30、40、50、60、80、100 | |

RL1-200 | 200 | 80、100、120、150、200 | |

RL1-400 | 400 | 150、200、250、300、350、400 |

AC contactor

model | rated current (A) | Induction coil voltage (V) | remarks |

CJ10-10 | 10 | exchange | |

CJ10-20 | 20 | ||

CJ10-40 | 40 | ||

CJ10-80 | 80 | ||

CJ10-150 | 150 |

.jpg)

.jpg)